Frame Details

The devFrame is designed as a simple box truss using printed parts on each end to clamp four tubes running between the ends. It provides a very strong structure with large internal volume, and minimal weight penalty when making the box longer.

The carbon fiber tubes are 10mm diameter on the box frame and 10mm or 12mm for the arm tubes. 10mm arm tubes are recommended for smaller and lighter builds up to about 400mm wheelbase, while 12mm arm tubes can be used when building +400mm wheelbase frames.

Interfaces

The devFrame has adopted a 15mm on center spacing for mounting accessories. There are also some parts such as the cross mounts which provide a range of 7.5mm on center hole spacing. The parts provide either through holes or pilot holes using this spacing.

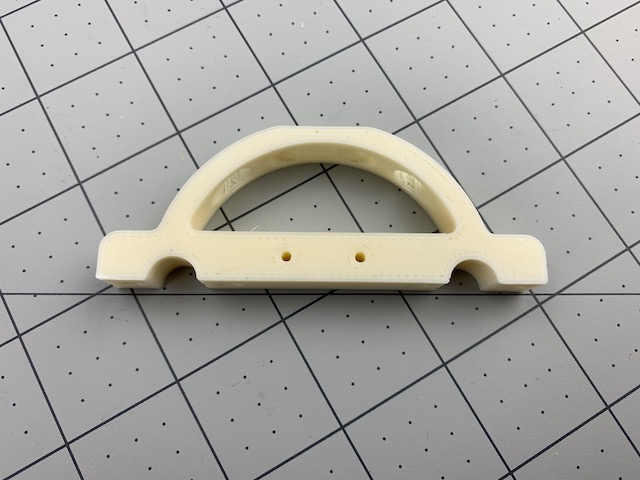

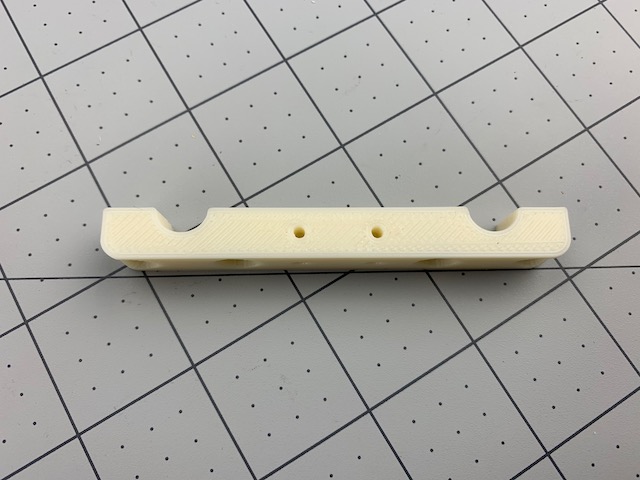

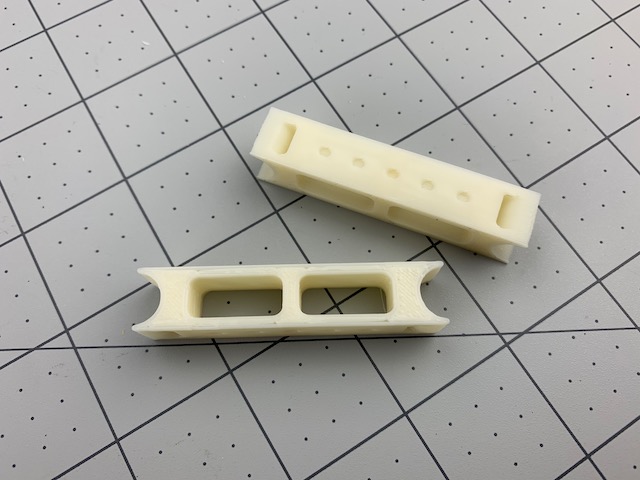

Cross Mounts with pilot holes

Cross Mounts with pilot holes

In general, when you see an accessory mount for the devFrame, it is typically adapting 15mm mounting hole spacing to whatever spacing is required to mount the accessory.

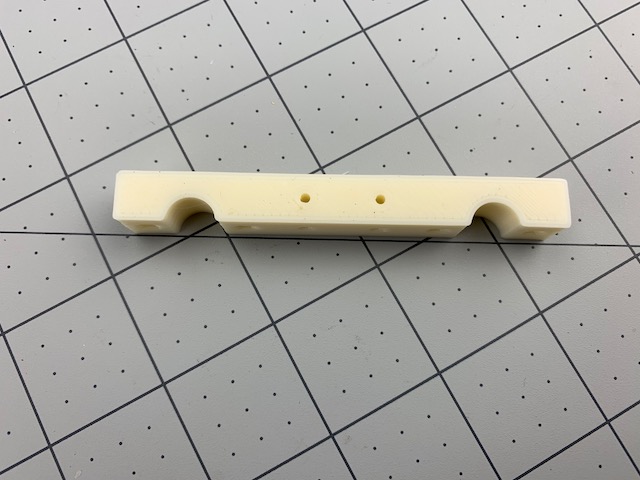

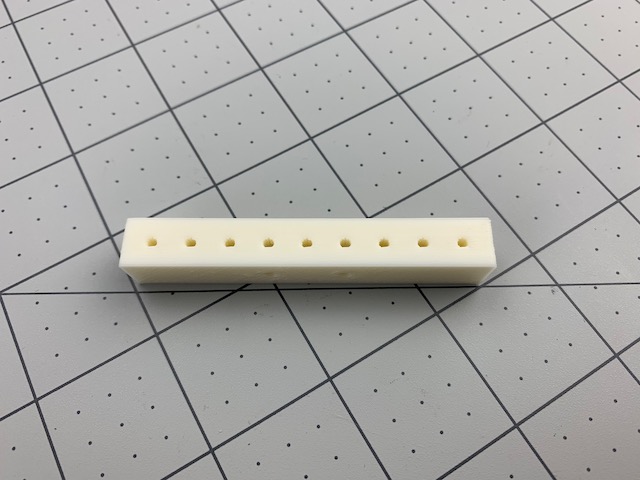

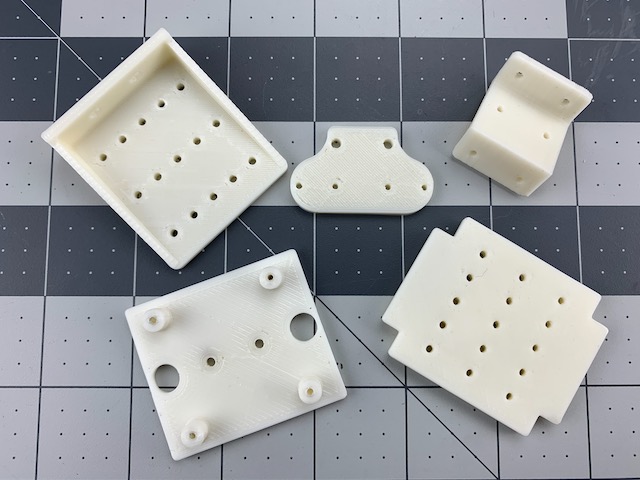

Mount assortment showing various through hole patterns

Mount assortment showing various through hole patterns

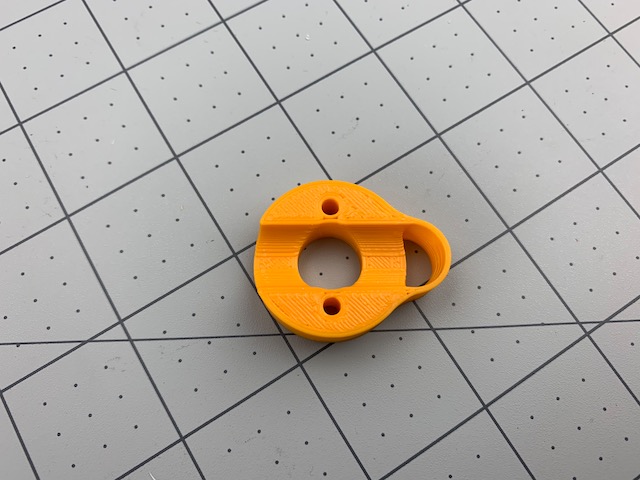

The Arm Tube Clamps support mounting either perpindicular to the centerline, as in an H Frame, or at a 30deg angle for Stretch X.

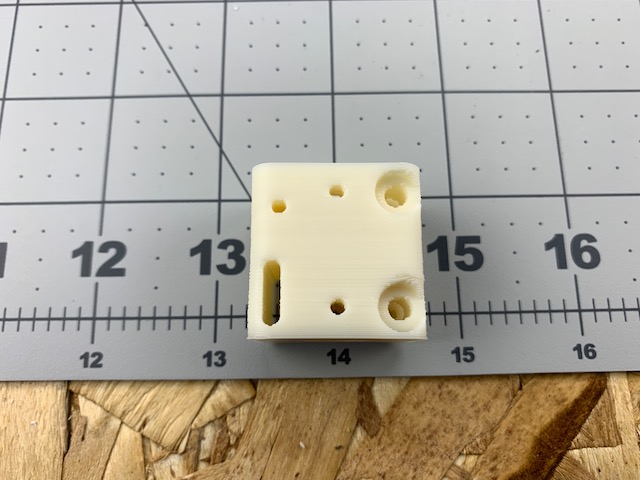

Top view of Arm Tube Clamp showing dual mounting options

Top view of Arm Tube Clamp showing dual mounting options

The 10mm box tubes are spaced 60mm on center laterally so they are compatible with off the shelf payload and battery mounts such as this Tarot gimbal hook.

3D Printed Parts

The following is a detailed list of currently available printed parts with build notes and print settings.

Frame

Box End Roll Cage

Description: Half tube clamp and adds roll cage for protection and mounting.

Notes: Typically paired with Box End square on top of frame ends. Also holds GPS and other mounts above frame. Two per frame is typical but one or none are options if a roll cage is not needed. Substitute Box End Rounded if not in use.

Print Profile: Standard

Box End Rounded

Description: Half tube clamp and is usually used on bottom of box end. Rounded outside corners avoid sharp edges.

Notes: Typically paired with Box End Square on bottom of frame ends. One per box end, two per frame if building with roll cage. Two per box end, four per frame if not using roll cage.

Print Profile: Standard

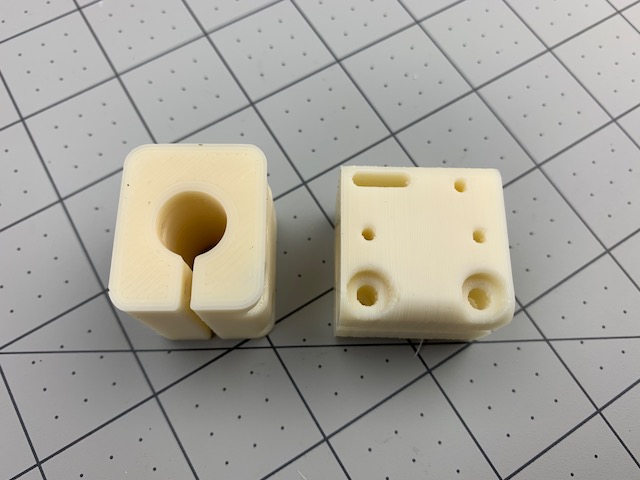

Box End Square

Description: Half tube clamp and is used in middle of box end.

Notes: Typically paired with Box End Roll Cage and Box End Rounded to form frame end tube clamps. Two per box end, four per frame.

Print Profile: Standard

Landing Gear

Description: Basic landing gear mounted to Box End Rounded to provide ground clearance.

Notes: Optional. One per box end, two per frame.

Print Profile: Standard

Landing Gear Spacer

Description: Mount between Landing Gear and Box End Rounded to add extra ground clearance and provide additional mounting points.

Notes: Optional. One per landing gear, two per frame.

Print Profile: Standard

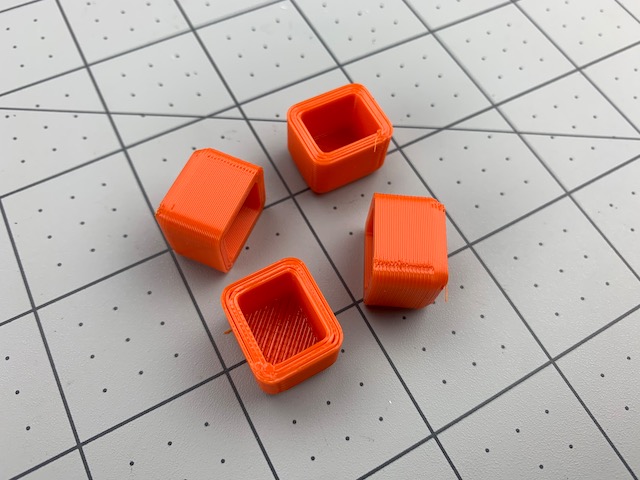

Landing Gear Cap TPU

Description: Slip on cap for landing gear legs that acts as shock absorber and provides better traction.

Notes: Optional. Two per landing gear, four per frame.

Print Profile: Solid

Arm Mounts

The mounts you use for the arms depend on the size of arm tube you select. 10mm and 12mm arm tubes are currently supported.

Arm Tube Mount 10mm

Description: Full tube clamp holds box end side of arm tube.

Notes: Four per frame when using 10mm arm tubes.

Print Profile: Solid

Arm Tube Mount 12mm

Description: Full tube clamp holds box end side of arm tube.

Notes: Four per frame when using 12mm arm tubes.

Print Profile: Solid

Motor Mount Half 10mm

Description: Half tube clamp used to mount motors with two 19mm spaced M3 screws.

Notes: Two per motor and eight per frame when using 10mm arm tubes.

Print Profile: Solid

Motor Mount Half 12mm

Description: Hale tube clamp used to mount motors with two 19mm spaced M3 screws.

Notes: Two per motor and eight per frame when using 12mm arm tubes.

Print Profile: Solid

Accessory Mounts

Various accessory mounts have been designed for sensors and companion computers. There are also some generic mounts that are very helpful to complete a build.

Print Profile: Solid

Carbon Fiber Tubes

The devFrame requires the use of roll wrapped carbon fiber tubes. They are not very cheap but they are very strong and light. We are using metric tube sizes to help with international sourcing of tubes. See our Resource page for more tube details.

Sizes

- 10mm carbon fiber tubes are used for the box frame, and arms for smaller builds

- 12mm carbon fiber tubes are used for the arms of larger builds

Each build will list the details of tube lengths and sizes used, but in general two 500mm lengths each of 10mm and 12mm should be enough to build a 450 class devFrame.

Caution – Using pultruded carbon fiber tubes is not supported as the clamping force created by the clamps can cause failure of the tube, and the frame itself.

Fasteners

The devFrame has been designed to use common fasteners to the maximum extent possible. Pan head screws in various sizes should be available at any hardware store. For more details about fasteners and standoffs see our Resource page.

The devFrame has been designed to use common fasteners to the maximum extent possible. Pan head screws in various sizes should be available at any hardware store. For more details about fasteners and standoffs see our Resource page.

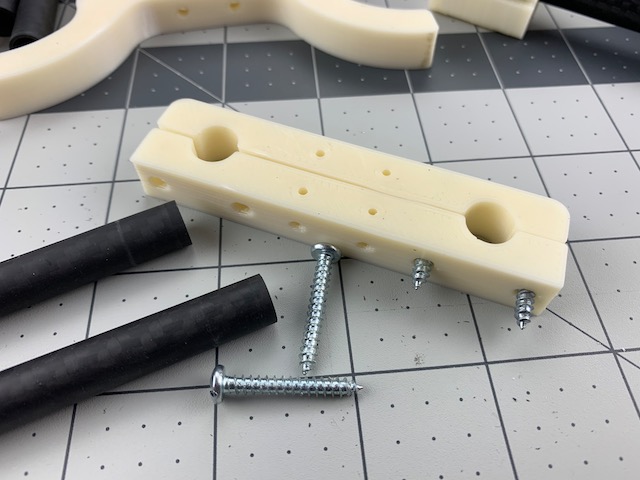

Note – Fastener nomenclature can be confusing. The devFrame is intended to be used with pan head screws with a pointed end and Phillips drive style. They are sometimes called sheet metal screws or self tapping.

Sizes

- #6 x 1in for Box Ends

- #6 x 3/4in for Arm Mounts

- #4 x 1/2in for Accessory Mounts

- #2, #1, #0 Varies Per Sensor

The detailed build documentation should call out the size and quantity of fastener required for each step in building the frame.